Edwards GXS750/4200 - REBUILT

Call for Price

| Weight | 2,101 lbs |

|---|---|

| Motor Power | 53.6 hp |

| Pumping Speed | 3,450 m3/h |

| Ultimate Pressure | 3.8 x 10-4 Torr |

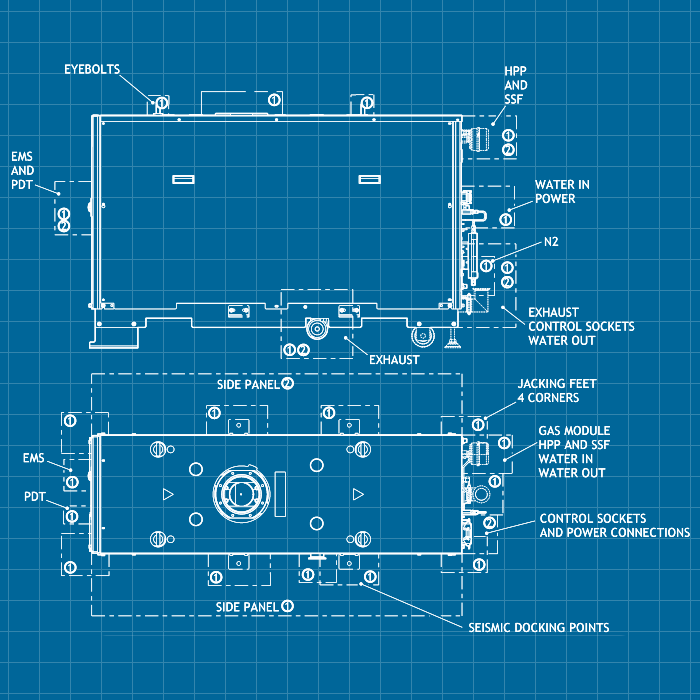

Edwards GXS750/4200 Industrial Dry Screw Vacuum Pump - REBUILT

With more than 90 years vacuum experience and over 150,000 dry pumps installed world wide, Edwards leads the way in every vacuum application including those handling harsh dust and process contaminants. Edwards GXS range incorporates our unique screw technology with a world leading high efficiency drive to achieve excellent vacuum performance and low running costs. With advanced temperature control, low maintenance and long service intervals, the GXS is the most robust and economical vacuum pump that establishes a new standard in dry pumping.

Questions? Please call our toll free number at 866-332-0500 or send an email to our sales team!

| Units | GXS750 | GXS750/2600 | GXS750/4200 | ||

|---|---|---|---|---|---|

| Peak pumping speed | m3h-1 (cfm) | 740 (436) | 2,300 (1,354) | 3,450 (2,031) | |

| Ultimate pressure (without purge) | mbar (Torr) | 3 x 10-3 (2.3 x 10-3) | 5 x 10-4 (3.8 x 10-4) | ||

| Full load power | @ ultimate pressure | kW (hp) | 10.0 (13.4) | 11.1 (14.9) | 11.5 (15.4) |

| @ peak pumping load | kW (hp) | 37.0 (49.6) | 40.0 (53.6) | 40.0 (53.6) | |

| Electrical | Supply options | High volt | 380-460V 3Ø 50/60Hz | ||

| Low volt | 200-230V 3Ø 50/60Hz | ||||

| Connection | High volt | Harting Han 100A-F | |||

| Low volt | Harting Han 200A-F | ||||

| Vacuum couplings | Inlet | ISO100 | ISO160 | ||

| Exhaust | NW50 | ||||

| Cooling water | Supply pressure (max) | bar (psig) | 6.9 (100) | ||

| DP across pump (min) | bar (psig) | 2.0 (29) | 2.5 (36) | ||

| Flow @ min DP | lmin-1 (gal/min) | 10 (2.6) | 12 (3.2) | ||

| Temperature | °C (°F) | 5-40 (41-104) High Volt variants 5-40 (41-86) Low Volt variants |

|||

| Connection | 3/8" BSP Male (G 3/8") | ||||

| Purge gas* | Pressure | bar (psig) | 2.5-6.9 (36-100) | ||

| Light duty | sl/min | 12 | |||

| Medium duty | sl/min | 18-146 | |||

| Connection | Swagelok® Ø ¼” tube with olive | ||||

| High flow purge/ solvent flush | Supply pressure | bar (psig) | 2.5-6.9 (36-100) | ||

| Control valve connection | Swagelok® Ø 3/8" tube with olive | ||||

| Filter connection | ½" NPT Female | ||||

| Solvent connection | 3/8" BSP Male (G 3/8") | ||||

| Mass | kg (lbs) | 640 (1,411) | 908 (2,002) | 953 (2,101) | |

| Noise (with suitable exhaust pipe) | dB(A) | < 70 | |||

| Operating temperature | °C (°F) | 5-40 (41-104) | |||

| Exhaust back pressure (MAX) | mbar (psia) | 1,400 (20) | |||

| System IP rating | Standard | 31 | |||

| Lubrication | Type | PFPE Drynert® 25/6 | |||

| Volume | l (gal) | 2.4 (0.6) | 3.1 (0.8) | 4.2 (1.1) | |

| Monitoring & Control |

Standard | Control | Front panel "Dashboard" Serial - RS232 | ||

| Monitoring | Ethernet Webserver | ||||

| Option | Control | Parallel - MCM MicroTIM | |||

| Control & monitoring | Profibus DP Pump Display Terminal (PDT) | ||||

| Monitoring | FabWorks® | ||||

| Pump combinations | Light duty | Shaft Seal Purge & High Vac Purge only | |||

| Medium duty | Shaft Seal Purge, High Vac Purge, Inlet Purge, variable Gas Ballast & Exhaust Purge (with Exhaust Pressure Sensor) | ||||

| Medium duty + purge | As Medium duty, plus High Flow Purge / Solvent Flush | ||||

| Type | Label | Description | Download |

|---|---|---|---|

| Edwards GXS Series - REBUILT | Instruction Manual | Download |

Need modifications to this item? PTB Sales' expert team of engineers can configure products to your specific needs.

Edwards GXS750/4200 Industrial Dry Screw Vacuum Pump - REBUILT