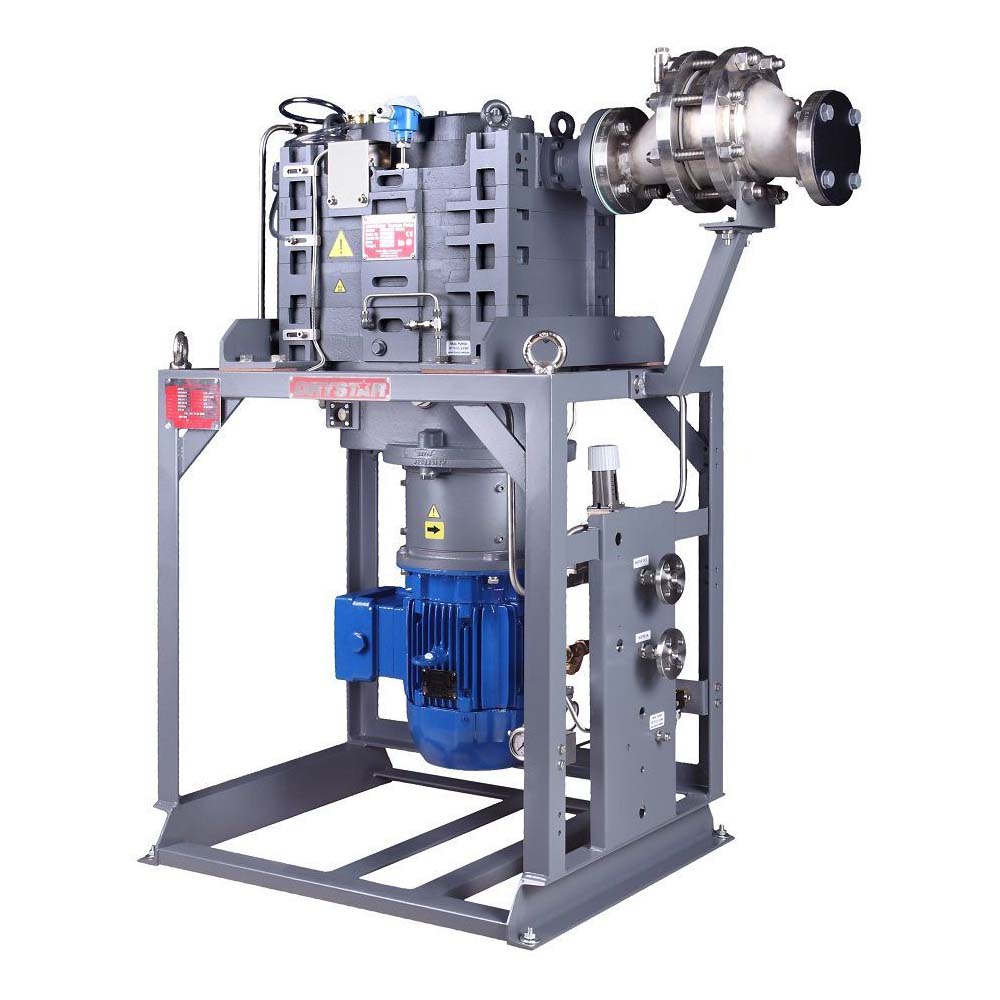

Edwards EDS 300 - NEW

Call for Price

| Weight | 1,100 lbs |

|---|---|

| Pumping Speed | > 280 m3/h |

| Ultimate Pressure | < 0.01 mbar |

Edwards EDS 300 Chemical Dry Vacuum Pump - NEW

The EDS dry pump range has been developed to meet the demanding requirements for pumping solutions in industrial and chemical applications. The EDS dry pumps are assigned ATEX certification enabling them to operate with hazardous atmospheres both internally and externally.

Questions? Please call our toll free number at 866-332-0500 or send an email to our sales team!

| EDS | 200 | 300 |

| Pumping speed w/out gas-ballast and w/out flame arresters | > 210 m3/h | > 280 m3/h |

| Ultimate pressure | < 0.05 mbar | < 0.01 mbar |

| Maximum permissible inlet pressure | 1,013 mbar | |

| Maximum permanent exhaust pressure (absolute pressure) | 1,190 mbar (for T3) 1,090 mbar (for T4) |

|

| Swept volume maximum pressure rating | 11 bar | |

| Integral leak rate | < 10-4 mbar 1/s | |

| Water vapour capacity without condensation at pressure between 10 - 50 mbar | 1.5 - 7 kg/h | 2 - 10 kg/h |

| Permissible ambient temperature* | -20 to +40°C | |

| Storage temperature | -30 to +50°C | |

| Typical continuous A-weighted sound pressure level at ultimate pressure (without silencer but long exhaust line) | < 72 dB(A) | |

| Relative atmospheric humidity | maximum 90% | |

| Installation location | up to 1,000 m (m ASL) | |

| Cooling (indirect cooled) | Water and Drystar water mix (50%) | |

| Mains voltage (only for motorized variants) | 400 V a.c. ± 10% | |

| Frequency (only for motorized variants) | 50 Hz | |

| Phases | 3-phase | |

| Motor rating | 5.5 kW (7.5 HP) 7.5 kW (10 HP) (for T4) |

7.5 kW (10 HP) |

| Current rating (380 - 400 V systems) at full load (5O Hz) | 11.5 A 13 A (for T4) |

15.4 A |

| Recommended branch circuit fuse | ||

| UL (200 - 230 V systems) IEC (200 - 230 V systems) UL (380 - 460 V systems) IEC (380 - 460 V systems) |

32 A 32 A 16 A 16 A |

|

| Minimum cable size for | ||

| 200 - 230 V systems 380 - 460 V systems 575 V systems |

6 mm2 4 mm2 4 mm2 |

|

| Power consumption at ultimate pressure | 4.1 kW (5.5 HP) 4.5 kW (6 HP) (for T4) |

4.5 kW (6 HP) |

| Installation category | II (IEC 60664-1) | |

| Input supply voltage unbalance | Should not exceed 2% when assessed over any one minute period | |

| Short circuit current rating according IEC/EN 60947 suitable for motors with efficiency class IE3. | 225 A | |

| Second protective earth (ground) conductor | Must be fitted with cross-sectional area at least equal to phase conductor size | |

| Pump body thermal snap switch | ||

| Supply voltage 1-phase | 6- 48 V d.c. | |

| Rotor speed | 6,600 rpm | 7,500 rpm |

| Minimum permissible motor speed1) | 20 Hz | |

| Protection class | IP 54 | |

| Approximate warm-up time to a temperature of 40°C (stator), with a cooling-water flow of 8 I/min at 20 °C |

60 minutes | |

| Oil filling | Ultragrade® Endurance Extend 110 | |

| Oil quantity: Drive (gearbox) Inlet side |

1,250 ml 250 ml |

|

| Vibration velocity | < 2 mm/s | |

| Inlet flange | DIN 80 / 3" ANSI Combination flange | |

| Exhaust flange | DIN 50 / 2" ANSI Combination flange | |

| Materials | ||

| Rotors, Stators, Shafts, Gearbox | Cast SG Iron | |

| Seals | PTFE and fluroelastomer | |

| Coupling cover | Cast grey iron, steel, aluminium, brass, rubber | |

| Timing gears | Steel | |

| Closed water circuit filling | Drystar coolant mixture 50:50 | |

| Oil filling | Synthetic oil | |

| Blow-off valve balls | Viton | |

| Weight (approximate) | 470 kg (535 kg with flame arrester) | |

| Water | ||

| Water connection | Gl/2" female threads | |

| Water supply temperature | ||

| T3 | 5°C - 35°C (direct cooled and indirect cooled) | |

| T4 | 5°C - 25°C (direct cooled) | |

| Minimum required cooling water flow | ||

| T3 | > 41/min (direct cooled and indirect cooled) | |

| T4 | > 8 l/min (direct cooled) | |

| Required water pressure differential (to achieve 8 l/min) | 0.2 bar | |

| Maximum supply pressure | 7 bar(g)** | |

| Primary cooling circuit volume (Drystar water mixture volume in case of variant w/ indirect cooling) | 6 l | |

| Purge | ||

| Connection | Gl/4" female thread | |

| Purge gas regulated pressure | > 2.2 bar(g) | |

| Purge gas supply pressure range | 4 to 10 bar(g) | |

| Purge gas supply quality | < 5 μm | |

| Seal purge flow rate | 12 slm total | |

| Gas-ballast flow rate | 0 to 50 slm (adjustable) | |

1) The minimum permissible speed is relevant for the oil lubrication of bearings and gears. Running the pump at less than the minimum speed for more than 1 hour can cause damage to the pump due to a lack of lubrication.

* at temperatures below freezing point, an appropriate mixing ratio with glycol must be observed.

** bar(g): bar(gauge) is the overpressure, for example, atmospheric pressure= 0 bar(g)

Need modifications to this item? PTB Sales' expert team of engineers can configure products to your specific needs.

Edwards EDS 300 Chemical Dry Vacuum Pump - NEW A41834985 EDS300 Chemical (ATEX} IEC ready 50 Hz indirect water cooled A41834986 EDS300 Chemical (ATEX} NEMA ready 60 Hz indirect water cooled A41832985 EDS300W Chemical (ATEX} IEC ready 50 Hz direct water cooled A41832945 EDS300ex 50 Hz 380-415V Cat2 T3 DC A41834945 EDS300ex 50 Hz 380-415V Cat2 T3 IC A41836945 EDS300ex 50 Hz 380-415 V Catl T3,T4 DC A41837945 EDS300ex 50 Hz 380-415 V Catl T3 IC