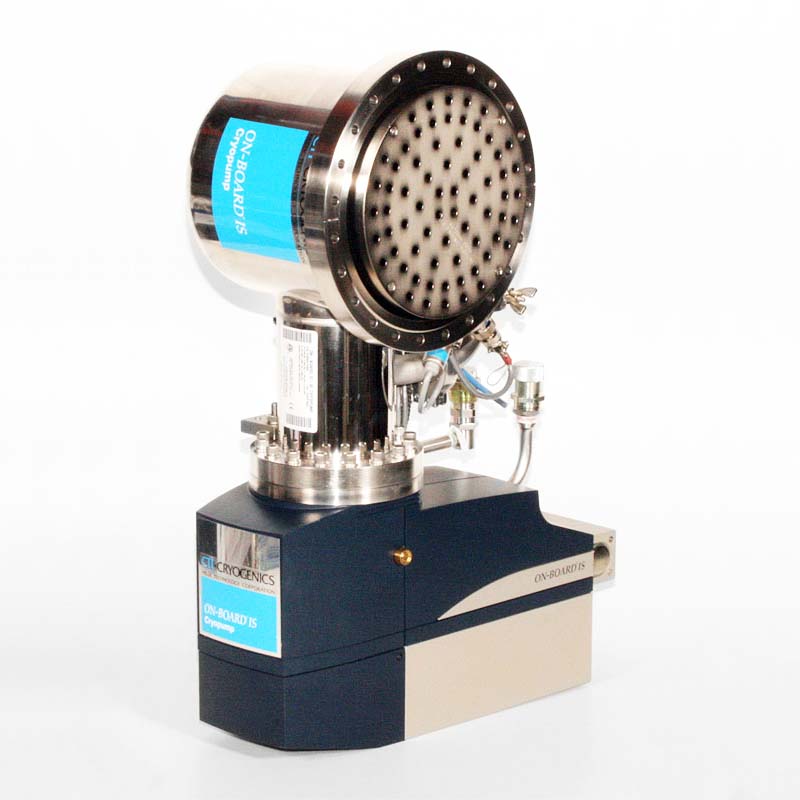

CTI On-Board 8F - SERVICE

Call for Price

Consumable parts vary with model type.

Brooks CTI-Cryogenics On-Board 8F - Scope of Work

One year warranty repair service.

PTB Sales will perform the following:

- Vacuum Side

- Replacement of the 15K array.

- All indium is replaced.

- 80K array inspected and remanufactured.

- Parts are cleaned and baked out.

- He leak checked to 1 x 10-8 cc/s.

- Helium Circuit

- Motor bearings and O-rings replaced.

- Refrigerator crankshaft bearings, O-rings, valve seals and springs replaced.

- Refrigerator timing set for optimal cryogenic performance.

- 1st and 2nd stage displacers cleaned, vacuum baked and rebuilt.

- Cryo Test

- Pump is fully charged with 99.999% ultra pure helium.

- Pump performance is verified per OEM’s published specifications.

- Cooldown time.

- On-Board communications functionality.

- On-Board temperature control functionality.

- All electronics are tested in an ESD controlled room to the OEM’s published specifications.

- Test data and QC Inspection sheets are attached and shipped with the cryopump.

View our inventory of rebuilt Brooks CTI On-Board IS, On-Board, and Cryo-Torr cryopumps.

Exceptional customer service and engineering support. Fast turnarounds. Low prices.

PTB Sales is the national leader in Brooks CTI-Cryogenics cryopump repairs.

Our state of the art 27,853 sq ft remanufacturing facility conforms to ISO 9001 quality standards, and is supported by an engineering team with over 90 years combined experience in vacuum technology. Our pump technicians, led by a factory-trained mechanic, have over 100 years combined experience.

Look no further. Let PTB Sales support your success.

White Papers:

- Cause & Effect of Helium Contamination on a Cryogenic Vacuum System

- Brooks CTI Cryogenic Vacuum System Compressor Preventive Maintenance

- Helium System Maintenance

- Pumping Condensable Vapors

- Initiate On-Board® IS Group Full Regeneration

- On-Board® IS 1st Stage Temperature Control

- Aborted On-Board® Regeneration Troubleshooting

- Identifying a Faulty On-Board® IS Module

- Cryo-Torr® Cryopump Regeneration Best Practices

Request an RMA Return Material Authorization

Procedures for shipping used equipment to PTB Sales:

- Seal off the exhaust and inlet of the pump.

- Attach our pump declaration form to the equipment to declare what contaminants the equipment has been exposed to.

There is a $300 Evaluation Fee. This gets applied to the cost of repair.

Questions? Please call our toll free number at 866-332-0500 or send an e-mail to our sales team!